HIGHLIGHTS

| Home > Machines > Vertical Wrapping > > FILLINGsystem - Sample system for a complete rinsing, filling, capping line (low viscosity) |

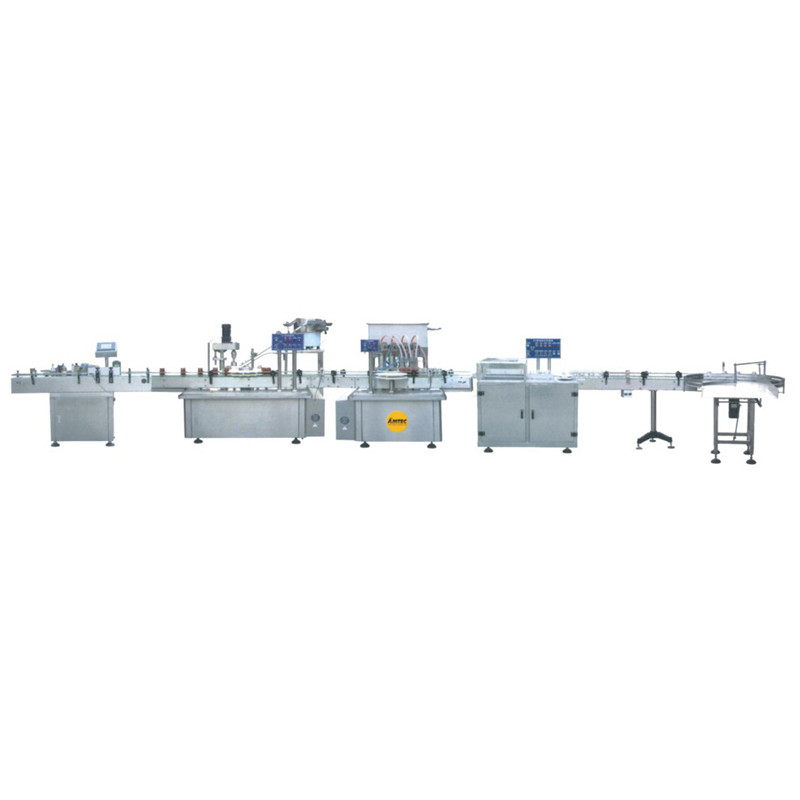

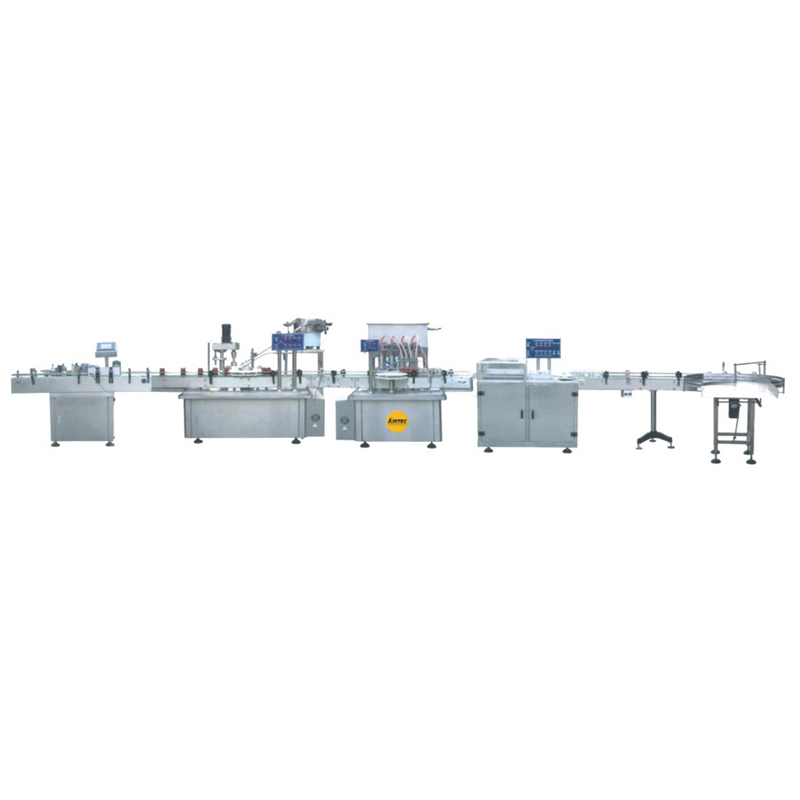

FILLINGsystem - Sample system for a complete rinsing, filling, capping line (low viscosity)

Sample system for a complete rinsing, filling, capping line

Sample filling system for low viscosity products (ketchup, jam, sauces, etc.) into bottles, glasses, cans. - Including container unscrambler, rolling bottle/container rinser, viscosity filler (hot filling, steam filling), vacuumize jar capper. - Specifications: filling volume 20-1000ml, bottle size range: diameter 20-150mm, cap diameter: 20-70mm, 4-12 filling nozzles allowing speeds of up to 6000 bottles/containers per hour. Tolerance of filling quantity: +/- 1%, yield of capping: < 99%, 380V, 3.5KW, 0.6m³, 6bar. - Please note: These are specifications for a sample system only. - The final specifications will vary. Please give us your packaging details (container size, shape, filling product, required speed, etc.) to prepare a full quotation for you.

Specifications

| Type of machine | Sample system for a complete rinsing, filling, capping line |

| Item number | F-GB-FLSYS13-LOWVISC |

| Bag weight / quantity * | - / 1000-6000 pcs/hour |

| Power / compressed air * | 380V / 3.5KW / 0.6m³ / 6bar |

| Dimensions / Weight | - / - |

*There may be deviations from these specifications. Please contact us. Gather the foil Specifications.

| BACK TO OVERVIEW |